THREE-STEP POUR & DEBRIDGE PROCESS

The three-step pour and debridge process, which includes a mechanical lock by either the Azo-Brader or Lancer method, results in an energy-saving window frame with the advantage of long-term durability that is warranted from structural deterioration.

TWO-PART POLYURETHANE

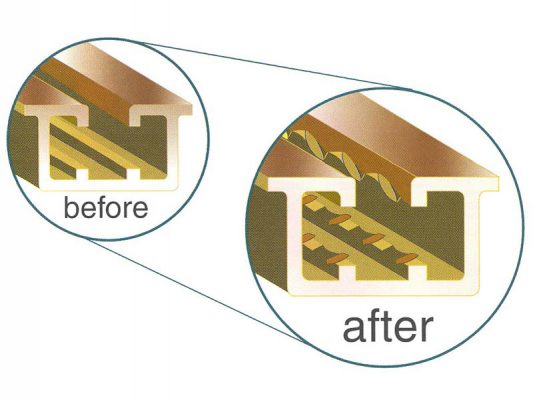

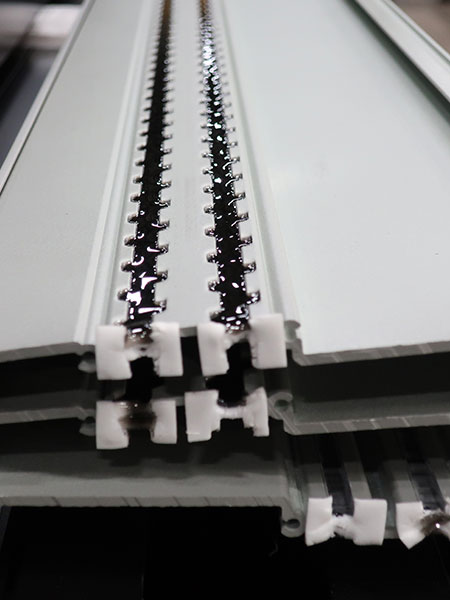

Pour-and-debridge thermal barrier systems use a two-part polyurethane that is poured into and cured within a “dog bone” structural cavity in the finished aluminum extrusion, after the cavity surface is conditioned using either the Azo-Brader or the Lancer machinery, to limit the bridge of metal that acts as a conductor of hot or cold temperatures on the exposed surface.

THE AZO-BRADER™

The Azo-Brader™ abrades the profile utilizing a carbide tool insert that reciprocates vertically to create raised projections on the thermal barrier pocket. The action of the tool is such that the aluminum is actually displaced under high velocity.

The Lancer™

The Lancer™ provides a unique method of punching the profile material to produce inward curving lanced indentations along the lugs in the pour cavity in such a way as to produce a structural mechanical lock. The Lancer also enhances the shear strength of the resulting polymer and aluminum composite..

The Azo-Brader and the Lancer mechanically lock the polyurethane polymer with the finished surface of the aluminum profile to ensure significantly improved adhesion. After the polyurethane has been poured into the cavity and solidified, the metal bridge from the bottom of the channel is removed to produce a true, non-metal-to-metal structural thermal barrier.