Agree on specification and expectations

In the architectural industry, the most recognized specification is AAMA-611. If specific parameters are required, it is important to furnish the finisher with the desired requirements to ensure the job is completed to the customer’s expectation.

Watch for welds

Welded parts will show a color difference on the weld versus the remainder of the part. The heat developed from the welding process can disturb the metallurgy on nearby metal and cause a localized discoloration after anodizing. Ensure the proper 5356 alloy welding wire is used, and the lowest heat possible

TALK RACKING

The finisher needs to know where parts can be racked. There are a variety of ways anodizers can rack parts, from welding material to spline bars, to a screw down bolt system. In any case, contact marks are visible on the aluminum. It is important to define what is acceptable and what is unacceptable with regard to exposed surfaces and rack marks.

handle with care

Good shipping practices are essential to a quality job. Prior to shipment to the finisher, package metal carefully to ensure the metal arrives dry and free of scratches and dents.

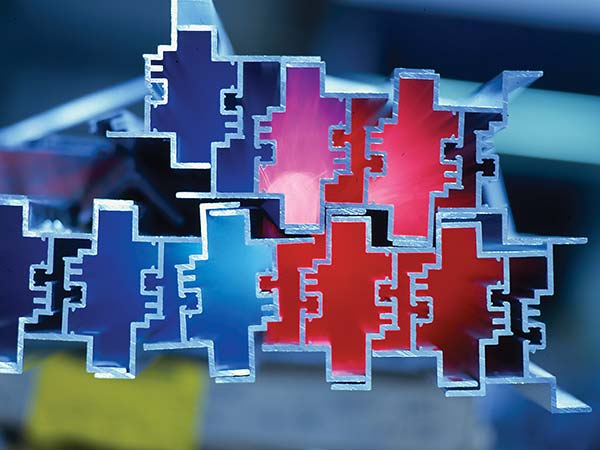

quality in, quality out

Metal free from defects will produce a higher quality finish. Avoid sending the finisher metal with scratches, dings, heavy die lines, die pick-up, etc. These metal quality defects will show through the anodize process.