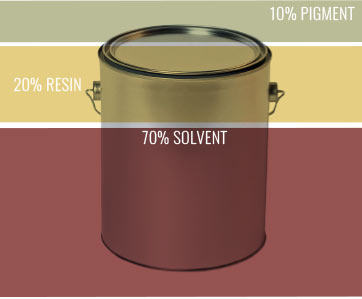

Bright, dramatic colors have always been an influential part of the color palette in architectural design. In the architectural coatings industry it takes certain pigments to get bright and exotic colors such as reds, oranges and yellows. The most commonly known pigments to achieve these colors are the minerals lead and cadmium.

These minerals are toxic to the human body and interfere with its functioning and undermine health. For the health and safety of our employees, our customers, and our environment it is Linetec’s position not to apply paint coatings containing lead, mercury or cadmium.

More than ninety percent of the colors that were previously formulated with lead- and cadmium-based pigments can be made to match the same color using the less harmful pigments. Of the remaining ten percent that can’t be matched exactly, colors will most likely be bright red, yellow, and oranges.

The exterior performance is equal to that of the old cadmium-based pigment product. You will see no performance loss due to this new formulation.