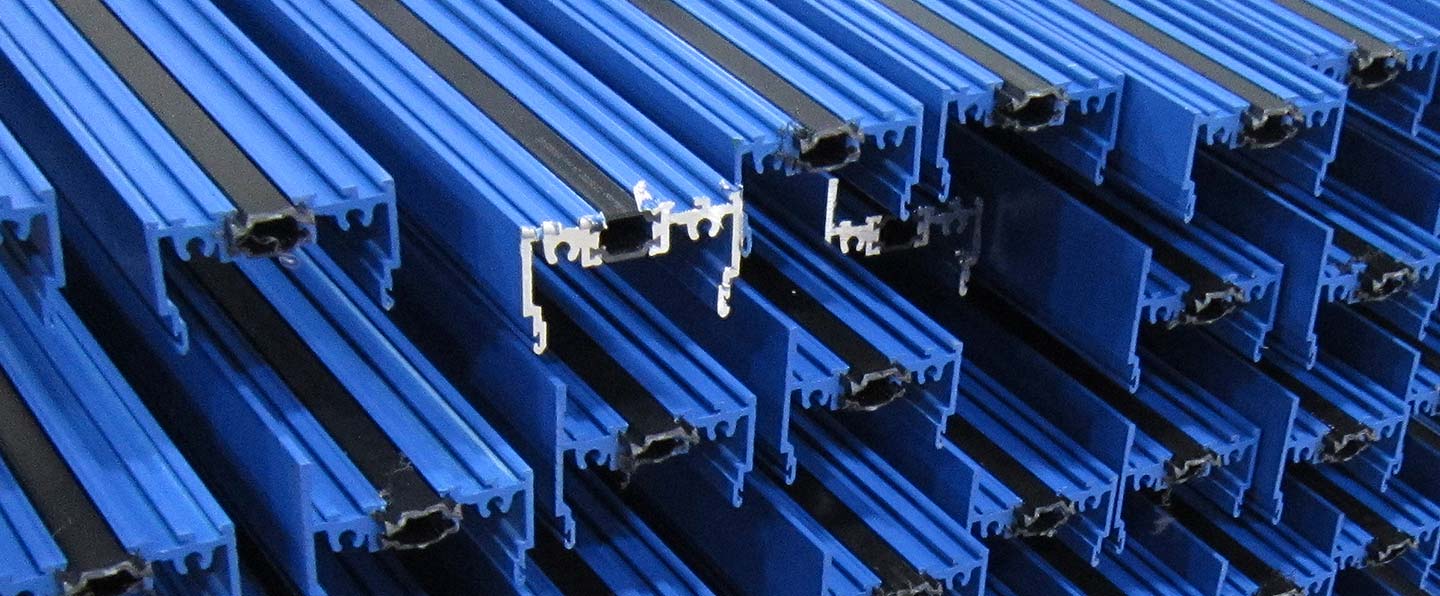

Crimping – Step 3 in Thermal Strut Process

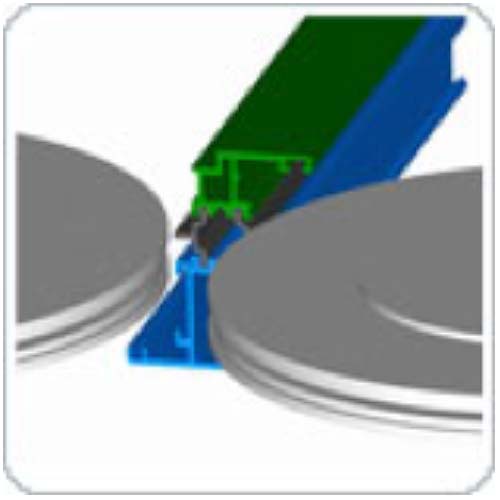

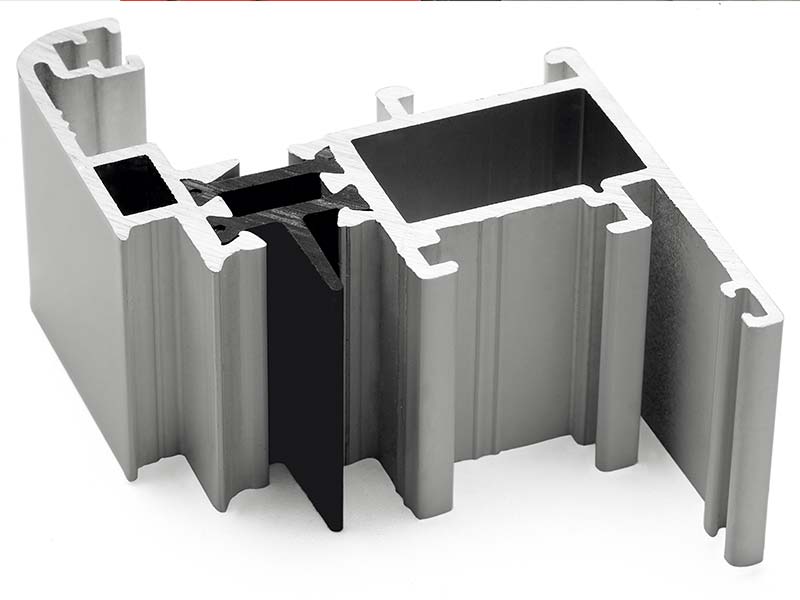

The crimping process uses three sets of wheels which rotate the aluminum on to the strut to mechanically lock it into place, forming the bond between the two extrusions and the strut.

The assembled aluminum and Strut profiles then act as a composite to transfer loads. Over 1300 pounds of pressure is applied in stages to crimp the aluminum. The first set of wheels applies 50 percent of the pressure while the second set applies 100 percent. The third set of wheels help to straighten the extrusion and completes the crimping process.

The crimping machine is set-up and adjusted for each new individual assembly. Adequate support must be provided to the assembly during the crimping process and sufficient pressure must be supplied to close the aluminum pocket tightly against the strut. Machine setups are determined the first time a particular assembly is run. Provided adequate shear values are attained, the machine settings are then recorded and used as a general guideline each time a particular assembly is required.

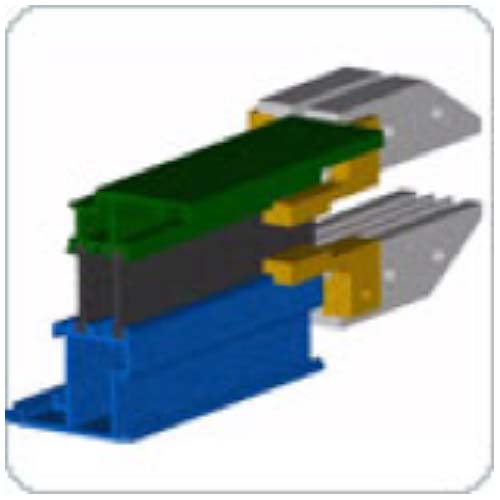

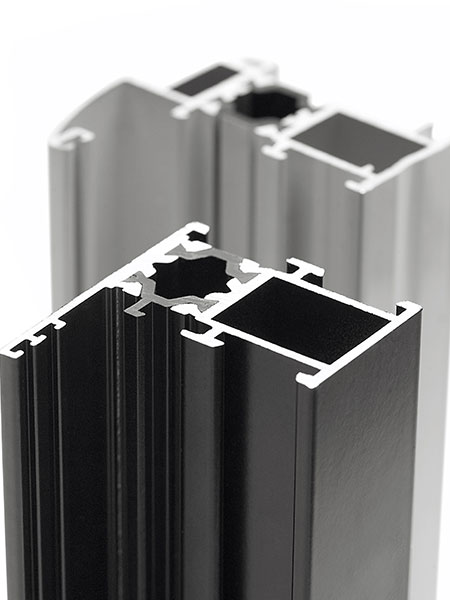

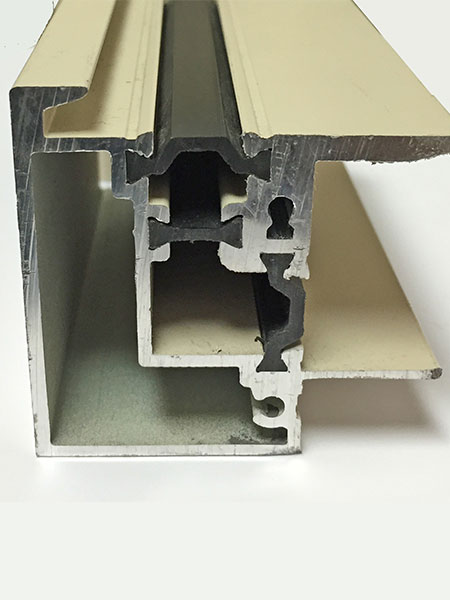

Thermal Strut involves two separate extrusions and joins them through the use of engineered structural polyamide plastic strut. Both the inside and outside aluminum profiles are extruded independently with a cavity that will ultimately receive the strut.

Thermal Strut involves two separate extrusions and joins them through the use of engineered structural polyamide plastic strut. Both the inside and outside aluminum profiles are extruded independently with a cavity that will ultimately receive the strut.