LMI Qualifications

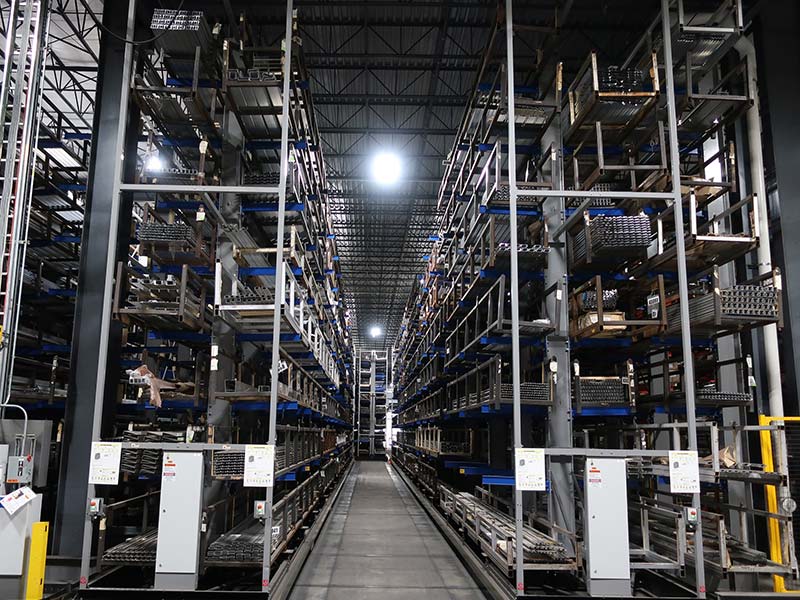

Linetec’s managed inventory program was developed to help our customers reduce overhead, optimize shipping costs, eliminate the “caught short-handed” scenario and shorten lead-times.

Combined with cycle counting and reporting services, with the following guidelines, the LMI service can be an extension of a customers’ own operation.

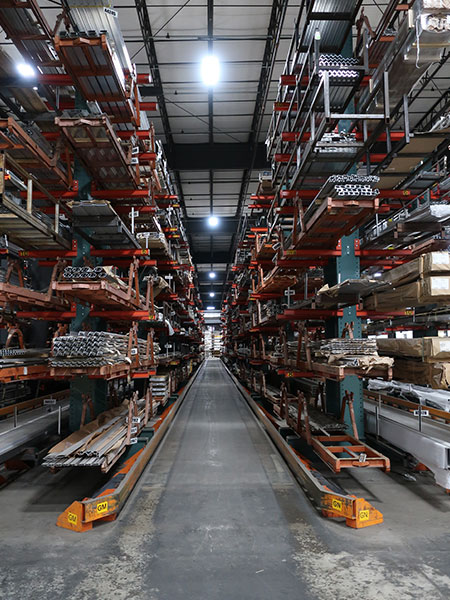

- Stored inventory should be in mill finish so liquid, anodize and powder coat orders can all be pulled from one inventory.

- Each inventoried profile can be stocked in up to two different lengths

- Inventory levels are agreed upon based on customers finishing needs

- Purchase orders can utilize both profiles pulled from inventory and project specific material sent to Linetec

- Linetec performs regular cycle counts and customer has real time visibility of allocated and available inventories on-line 24/7