FROSTIER MATTE APPERANCE.

ACID-ETCH ANODIZE

The etch process is designed to dissolve a thin layer on the surface of the aluminum to develop a smooth uniform finish. Linetec made the change to its etch chemistry from traditional caustic etch to a more eco-friendly etch process, referred to acid etch.

Etching is a vital step during the anodize process

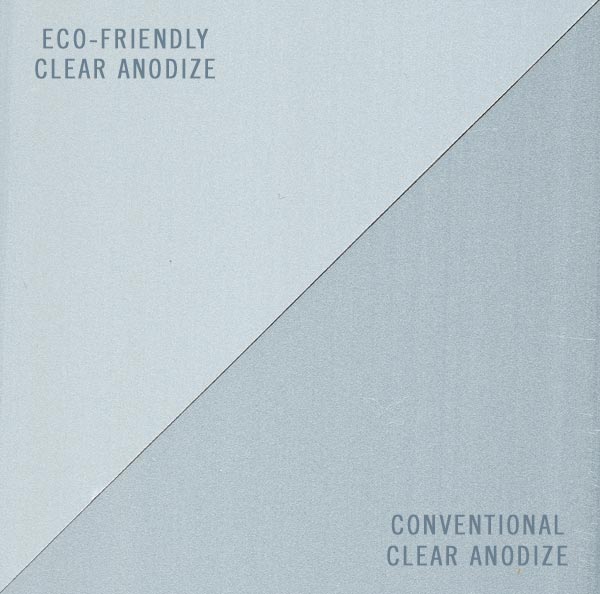

These images depict conventional anodize samples on the bottom and eco-friendly (acid etch) anodize samples on the top.

Neither the conventional etch process nor the eco-friendly etch process removes irregularities in the aluminum, but the eco-friendly etch does a much better job of concealing them.

Environmental Benefits of Acid Etch Process

- Environmental Benefits of Acid Etch Process Secondary billet can be successfully anodized, contributing to recycled material content by green building programs

- The eco-friendly etch process reduces landfill waste by 75-80%

- The process byproducts from the etching process are recyclable

- Reduction in energy used for waste treatment process

Eco-Friendly anodize include

Linetec’s Anodize process offers a superior aesthetic finish and a more environmentally-friendly product with this acid etch technology.

The eco-friendly etch process creates an aesthetically appealing “frostier” appearance that helps hide small defects, such as die lines, flow lines, minor corrosion and scratches, that may occur on the aluminum surface of architectural products. Although neither conventional caustic nor acid etch removes all irregularities in the aluminum, acid etch does a better job of concealing them. This gives the material a better aesthetic finish on both primary and secondary (recycled) billet.

Linetec’s eco-friendly anodize process meets or exceeds all AAMA 611 specifications. Standard warranty of 5 years with optional extended 10 year warranty available.

BENEFIts of anodize ACID-ETCH include

SUPERIOR AESTHETIC FINISH

Superior aesthetic finish – produces a frostier matte (most evident in clear anodize).

HIDES DEFECTS

Hides small defects on the aluminum surface such as die lines, flow lines, minor corrosion and scratches.

REDUCED GLARE

Low gloss level reduces glare in bright sunlight. Gloss level reading is reduced from 16 to 24 with conventional anodize, down to a gloss level of four.

CONSISTENT TOLORANCE

Aluminum removed during the etching process is reduced by 80%, down to 0.5 mils, allowing for a more consistent extrusion tolerance between paint and anodize.

Enhance durability/lifecycles

The etch process has the viscosity of water and will not collect in the small recesses of aluminum extrusions or narrow aluminum tubes, enhancing the durability and lifecycles of the finished product.

eco-friendly anodize

Conventional anodized material can be converted to eco-friendly anodize and vise versa.

Specify Eco-Friendly Anodize – M10C21A44

AAMA Verified Component Licensee

American Architectural Manufacturers Association, a material-neutral organization, is the source of performance standards for the fenestration professionals of window, door, skylight, curtain wall and storefront manufacturing companies.

LEARN MORE

SPECIALTY FINISHES

As your Single Source Solution we offer custom options and specialty finishes such as Wood Grain Finishes, Copper Anodize, Spattercoat and textured Terra Cotta Coatings.

LEARN MORE

ENVIRONMENTAL COMMITMENT

Linetec has earned a long-standing reputation as a leader in environmentally-conscious practices and finishing options. For more than a decade, environmental responsibility has been written into our core values.

LEARN MORE

RESOURCE CENTER

Our technical experts at Linetec provide valuable industry education of high-performance architectural finishes to architects, engineers, specifiers and manufacturers.

LEARN MORE

Photo credits: Loewen, Major Industries

Architectural Paint

Architectural Paint Types

Color Charts

Request Samples

Request for Quote

PAINT SPECS & PROCESS

Linetec Paint Process

In-House Blending

Quality Control

Material Size Guidelines

AAMA Specifications

Warranty Information

Environmental Considerations

PAINT MAINENTANCE

ANODIZE FINISHING

Copper Anodize

Eco-Friendly Anodize

Anodize Color Samples

Request for Quote

Declare | Red List Free

ANODIZE SPECS & PROCESS

Anodize Process

Racking Methods

Quality Control

Material Size Guidelines

AAMA Specifications

Warranty Information

Environmental Considerations

ANODIZE MAINENTANCE

LINETEC SERVICES

Linetec Managed Inventory (LMI)

Stretch Forming

Linetec Trucking

Thermal Pour & Debridge

Thermal Strut

Brake Metal & Fabrication

Stock Flat Sheet & Extrusion

Packaging & Shipping

SPECIALTY FINISHES

Copper Anodize

Bordeaux Anodize

Wood Grain Finishes

Terra Cotta Coatings

Spattercoat

Request A Quote