During winter months and in cold climates, most people look forward to staying warm, cozy indoors even if they’re sitting next to a window. However, many of us are all too familiar with a chilly draft or even a frosted interior surface that cause everyone to distance themselves several feet from the windows.

When the cold is kept outside and the warmth kept inside, we’re happier, more comfortable and more productive. Thermally improved aluminum framing and high-performance glass reduce heat transfer and condensation in windows, skylights, curtainwall, storefront and entrance systems.

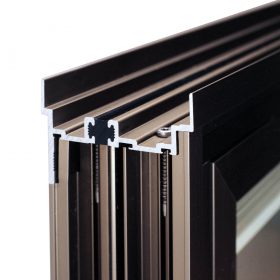

Although the aluminum framing on these systems is extremely strong, light and nearly maintenance free, aluminum is a poor insulating material and rapidly conducts heat. By separating the interior and exterior of the frame or window, the aluminum framing should be thermally broken, or thermally improved, to reduce this unwanted heat flow and the resulting disruption to the interior temperature.

Helping preserve people’s comfort, a thermally improved framing system greatly improves the performance, reducing the window system’s U-Factor (the measure of heat transfer, where lower is better), by separating the aluminum profile into two parts. This maintains the window system’s structural and long-term durability. The two methods for doing this are polyurethane poured-and-debridged or polyamide insulating strips (thermal strut) systems.

For most building owners and occupants, high thermal performance is an increasing expectation. Thermally improved aluminum framing members can:

- Help meet model energy codes for new construction

- Contribute to efficient building performance when renovating existing buildings

- Reduce the HVAC load for optimally sized equipment and operation

- Save energy costs, conserve resources and reduce associated emissions

The American Architectural Manufacturers Association details stringent industry standards of the two thermal improvement methods in AAMA QAG-2, “Voluntary Quality Assurance Processing Guide for Polyamide Thermal Barriers” and QAG-1, “Quality Assurance Processing Guide for Poured and Debridged Polyurethane Thermal Barriers.”

Following AAMA QAG-1 and -2, Linetec offers both poured-and-debridged and thermal insulating strut, backed with an industry-leading warranty. Choosing the thermal strut system provides the additional design flexibility of dual finishing, where the interior and exterior aluminum surfaces may be finished in different colors and finish types.

Linetec is one of the only architectural finishers in the U.S. to provide a full pour-and-debridge of radius material, both structural and non-structural, and a fully crimped thermal strut system for curved and radius finished aluminum extrusions. For curved extrusions, installing the thermal barrier in the metal after it has been stretch formed helps minimize stress on the thermal barrier and ensures performance as specified.

Linetec places no restrictions on the degree of curvature, which can be finished with either architectural paint coatings or anodizing. Regardless of the effect the curving process has on the finish, nearly all manufacturer and applicator warranties are voided when extrusions or brake metal are finished prior to curving.

Linetec places no restrictions on the degree of curvature, which can be finished with either architectural paint coatings or anodizing. Regardless of the effect the curving process has on the finish, nearly all manufacturer and applicator warranties are voided when extrusions or brake metal are finished prior to curving.

As a single source solution, Linetec alleviates this worry and performs all the services in the proper order allowing its customers to retain the full finish warranty. This peace of mind and the high thermal performance contribute to the long-term benefits enjoyed by the building owner and occupants.