To meet model energy codes and building-specific energy efficiency objectives, manufacturers thermally improve their aluminum-framed windows, entrances, skylights, curtainwall, storefronts and other exterior-facing fenestration products.

To meet model energy codes and building-specific energy efficiency objectives, manufacturers thermally improve their aluminum-framed windows, entrances, skylights, curtainwall, storefronts and other exterior-facing fenestration products.

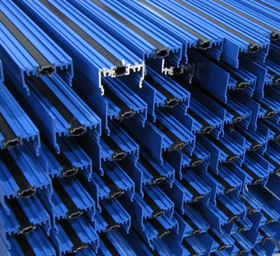

As a single source solution, Linetec offers you more choices, fewer steps and less hassle to ensure high-quality, finished aluminum that meets the thermal performance requirements of your customers’ building envelopes. Whether choosing thermal strut or poured-and-debridged, the goal is the same: reduce heat transfer, and as a result, lower energy consumption and keep the occupants inside more comfortable.

You’re getting warmer

Heat, or thermal energy, is created by the intrinsic movement of atoms and molecules in matter. When they move faster, they create more heat. When this thermal energy moves between systems, it is referred to as heat transfer and is measured by temperature. Thermal energy always transfers from a system of higher energy to a system of lower energy, or from hot to cold.

Heat is transferred in three main ways:

- Radiation –transfers heat by electromagnetic energy, also known as infrared radiation (IR). Even though the sun is 93 million miles away, it produces IR waves that travel through space to heat the Earth.

Traditionally, we’ve used trees and other natural shading to block sunlight. Umbrellas, canopies, awnings and other manufactured shading devices are incorporated into today’s built environment. In modern fenestration systems, the glass also can be coated to reflect IR energy and further manage unwanted solar heat.

- Convection – transfers heat though the mass movement of particles in either a gas or a liquid. As a mass of air or liquid heats up, the particles naturally expand and become less dense, causing the warm air or liquid to rise and to push cold masses down. This often creates a circulatory effect, such as seen within weather systems or convection ovens. In cooking appliances, this feature turns on a fan within the oven to circulate the hot air, resulting in faster and more even cooking.

Most building’s HVAC systems also use mechanical convection to heat or cool interior spaces. If you open a window, convection will happen through natural ventilation by either letting hot air inside if it’s warmer outside, or allowing hot air out if it’s warmer inside. Because hot air rises, opening transom and clerestory windows near the ceiling helps let out warm air, keeping the cooler air at floor level.

- Conduction – transfer heat directly from one object to another. Thermal energy moves from molecule to molecule through physical contact, spreading heat through solid objects. You have experienced conduction if you have warmed your feet on a sand beach or burned yourself on the hot handle of a pan.

Metal is a particularly conductive material, and aluminum has very high thermal conductivity. This can be a useful property for numerous applications like cookware, packaging and electronics, but it also can be challenging to manage in exterior building materials, such as fenestration framing systems.

A good break and a welcome disruption Without a thermal barrier to separate the aluminum framing’s exterior and interior surfaces, energy will transfer through it causing heat loss from the interior when it’s cooler outside or heat gain when exterior temperatures are warmer.

Without a thermal barrier to separate the aluminum framing’s exterior and interior surfaces, energy will transfer through it causing heat loss from the interior when it’s cooler outside or heat gain when exterior temperatures are warmer.

Uncontrolled, this can interfere the building’s HVAC systems, increase energy use and costs, and lead to unproductive, irritable occupants. Adding a thermal “break” and insulating material effectively disrupts the heat transfer in aluminum-framed fenestration products. Linetec offers a choice of either polyamide strut or polyurethane poured-and-debridged thermal barrier systems.

Working with your product engineers, we can meet your thermal barrier specifications for high-performance, finished fenestration systems that help achieve your customers’ energy efficiency objectives.

For personalized assistance with your thermal improvements needs, please contact your local representative.