Metallic and mica coatings draw attention to finished aluminum products and the architectural features and façade systems they create. The size and reflectivity of the flakes in the coating, their orientation, and the degree to which they are all oriented in the same direction will affect the finish’s appearance. This is sometimes referred to as the “flop of the flake.”

As an experienced finishing service provider, Linetec can help you achieve the greatest sparkle and depth from these specialty coatings, while minimizing visible variation.

Optimal Optics

In an optimally applied metallic or mica coating, the flakes are randomly oriented.

Like tiny mirrors, the flakes that lie horizontal in the paint will reflect the most light. If all the flakes in the coating were to lie horizontally, the maximum amount of light would be reflected. The surface would look very bright to the point of appearing almost solid rather than sparkling. If the metallic flake content is too high, the shimmer also is diminished and again, it will appear to be solid color paint rather than metallic.

Taken to another extreme, if all the metallic flakes were to lie vertically in the paint, very little light will be reflected. The surface would appear very dark and possibly eliminate the coating’s intended brilliance.

With all of the variables to control in spray-applied metallic coatings, the reality is that some inconsistencies will result. The first step in managing and minimizing visible variation is to recognize and mitigate for the greatest risks.

Controlled Consistency

Be aware that the same qualities that create the vibrancy and reflectivity of metallic and mica coatings also can cause variations in appearance within a project, an elevation, or even a single part of a metal building product.

A project with lots of aluminum wall panels is more likely to show variation than one with extrusions, such as on window or curtainwall framing, or one with panels separated by masonry or other materials that disrupt the overall visual continuity of a building’s exterior. We recommend painting the same elevations and adjacent panels on the same application run.

We also strongly suggest that your paint is made in a single batch, especially when working on a large project or one with multiple phases. Similarly, a single finisher should apply the paint to ensure the greatest consistency and quality control. This will minimize the potential variation between different paint applicators and their different equipment.

Managing Metamerism

Visibly acceptable color ranges will measure within specification, as matching from panel to panel, under laboratory controlled conditions, but can be perceived as non-matching when installed on the project. The difference in actual versus perceived color is known as “metamerism.”

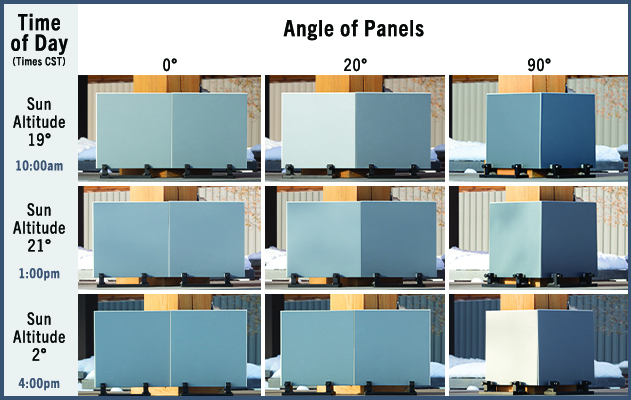

Remember that sunlight and shade reflect color differently, and that metamerism will be experienced differently throughout the day and the year. The reflective properties of the metallic and mica flakes means that the same painted surface will look different depending on the viewing angle, the angle of the sun or other light source, and the intensity and type of the light source.

Metamerism also can present challenges when creating and viewing samples. A complete color range of sample variations is not possible with these paints since the “color space” is a three-dimensional sphere and there are an infinite number of directions a color can range.

For most realistic metallic paint samples, review a sample in the “L-scale.” The L-scale is one of the three axis points in the Lab color sphere and the one that best measures brightness. Also, request color chips from us, the finisher, rather than the paint manufacturer. Different application equipment can result in a slightly different color or appearance relative to the paint manufacturer’s laboratory-produced samples.

Silver Suggestions

Some metallic colors have a greater propensity for visible variation. This can be particularly noticeable with bright, semi-transparent colors, such as silver metallics. As soon as you know that bright silver coatings are specified, let’s talk. We want to ensure the finish meets your expectations. We also may want to discuss alternatives, such as mica coatings or clear anodize.

Mica paint coatings provide a similar appearance with sometimes slightly less brilliance or depth. These two-coat systems are manufactured with a non-conductive mineral rather than with conductive metal flake. Due to their organic formulation, they eliminate the need for a clear coat, are less sensitive to flake orientation and minimize visible variation improving the overall color consistency.

When a uniform aluminum alloy is specified, an anodize finish can enhance the metallic aesthetic and also can show less visible variation than the flop of the flake phenomenon seen with painted metallic coatings.

Whether your project calls for a sparkling Champagne, a glittering Sapphire, a jeweled Jade or a perfect Platinum, we can help ensure your material is finished to present the optimal brightness and color.

For personalized assistance with your coating selections or other finishing service needs, please contact your local representative.