The human eye can differentiate between 10 million colors, and the way in which buildings are built and lit can alter that perceived color. Humans have been making and using paint colors for hundreds of years, however current paint technology still means we live in a world of variables and, while they may be very small, they can still be significant.

In most cases the visual difference in painted coatings on a building are minimal. To help minimize color-matching issues keep in mind these Top 7 points:

- When selecting and approving color chip samples for your project, view them outside, under natural light, rather than in an office with artificial lighting. Paint chip samples should be viewed under the light source in which the finished project will be seen. The appearance of a color also can be altered by the height, angle and distance of the light source. The time of day and the time of year can influence the visual perception of a color. Atmospheric conditions also can alter natural light.

-

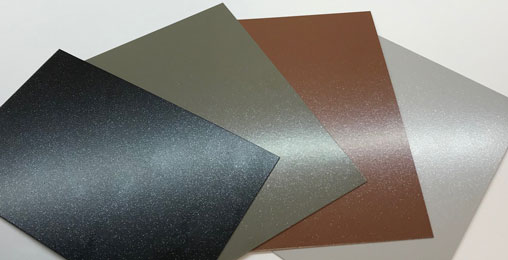

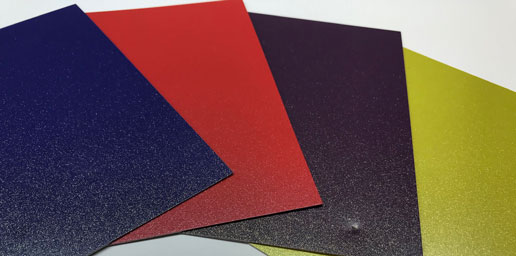

Mica and metallic coatings will reflect different appearances according to nearest light and the orientation of the individual flakes within the coating. Paints containing mica or metallic pigments will show some variation in appearance caused by an extensive list of variables, some of which are uncontrollable. (Read more) The color of metallic coated pieces will change with viewing angle. This is due to the flop of the metallic flakes within the coating. These flakes give the coating a depth of color that is visually exciting, but it also makes perfect color uniformity unattainable. Panels that appear the same color when viewed in the same plane will look different if tilted only a few degrees out of level with each other.

Linetec can offer options, to the standard mica and metallic coatings, that will give your finish an incredible amount of sparkle and shine, and do not have the flop-of-the-flake tendencies. For more information contact us.

Linetec can offer options, to the standard mica and metallic coatings, that will give your finish an incredible amount of sparkle and shine, and do not have the flop-of-the-flake tendencies. For more information contact us. - Sample chips are prepared in a lab, while project material will be painted in the production line. Please remember that the lab and production line operating conditions are not the same; temperatures, humidity, cure process and other variables can affect the color difference. Gloss and surface characteristics may vary from sample chips to the actual aluminum used for the project, as color can appear different over different metal types and alloys.

- Defects on the aluminum surface can cause color variation. A sanded area of the aluminum may appear darker than unsanded areas. A paint coating will not always cover scuffs and scratches on the aluminum.

- Color matching problems can occur when multiple coating applicators are used. Applicators have various levels of technologies and methodologies. The more enhanced the applicator’s technology and equipment, such as automated lines, the less risk of color variation.

A batch of paint created by one applicator can vary slightly from a batch created by another applicator or by the paint manufacturer. The only way to guarantee a nearly perfect color match is to have all the material painted at one time from the same applicator, from the same batch of paint

- Choosing the same color in different resin systems, such as Fluoropolymer and baked enamel, doesn’t always create the exact same color; and over time, the color difference will increase dramatically as each resin system weathers at a different rate. If more than one performance specification is required, match and approve colors in each resin system prior to application. The color difference is most often due to the different surface texture and gloss of each coating type.

- Avoid the use of touch-up paint when possible. Touch-up paint will never match the exact color, gloss and texture of the factory-applied paint.

Before final color approval, obtain painted sample chips from the selected applicator(s) for your project.

Paint color range samples are not typical, as they would be with an anodize color sample. Most often, a standard color is selected and approved. Providing a color range for a single paint color would mean hundreds of combinations of ranges around that single color point. Therefore, a “standard” is produced and color variance is measured from that standard.

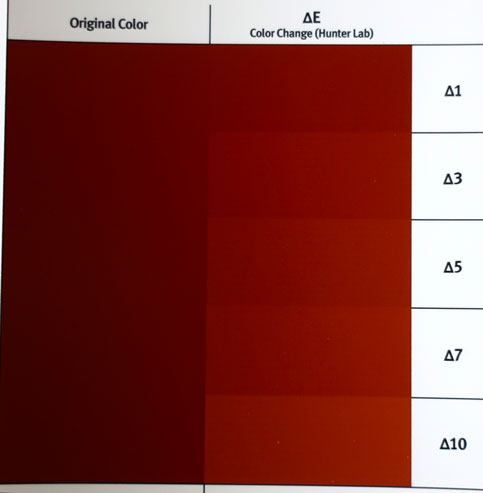

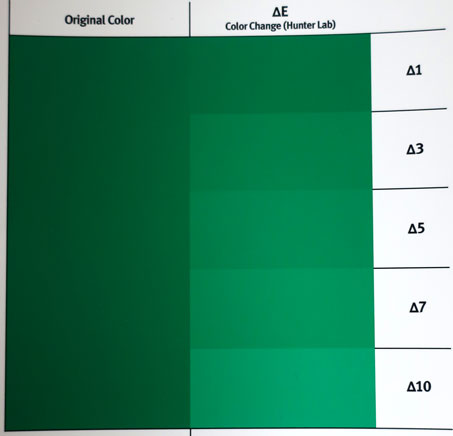

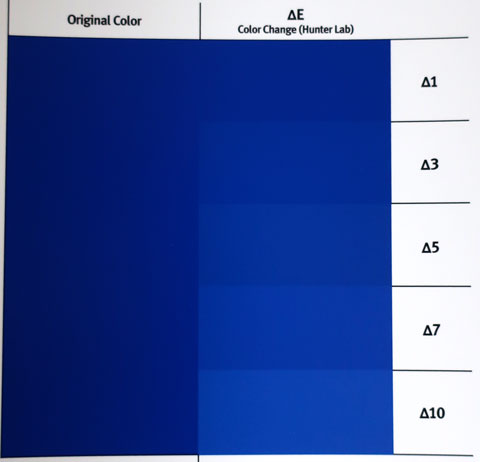

Paint color is most often measured by a color scale, either Hunter, CIELAB or CMC. These scales are composed of three numbers, usually L, a, b. The scales are three-dimensional and the mathematical difference between any two points is described as a Delta E. This Delta E is an attempt to state in one number the color difference between two test points. The industry accepted and understood color range for paint coatings is 2 Delta E, which is noted in the industry standard AAMA 2605 specification.

The images above are examples of red, green and blue Fluropolymer 70% PVDF paint coatings representing the visual color difference at Delta E measurements of 1, 3, 5, 7 and 10. Color change in these examples is on the lightness direction (L) of the L.a.b. scale.

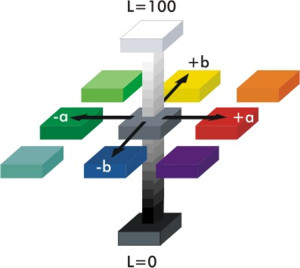

A Lab color space is a color-opponent space with dimension L for lightness and a and b for the color-opponent dimensions. With the Lab scale:

“L” is Light to Dark

“a” is Green to Red

“b” is Blue to Yellow

Color is three dimensional (imagine a sphere) and therefore is measured from a point, rather than by a range.

Please contact us for additional assistance in effectively managing color expectations for your building projects.

Printable PDF of this Blog

Linetec can offer options, to the standard mica and metallic coatings, that will give your finish an incredible amount of sparkle and shine, and do not have the flop-of-the-flake tendencies. For more information

Linetec can offer options, to the standard mica and metallic coatings, that will give your finish an incredible amount of sparkle and shine, and do not have the flop-of-the-flake tendencies. For more information