What Is Touch-Up Paint?

Upon request, and dependent on job size, applicators may supply a limited amount of touch-up paint with completed projects. Touch-up paint is supplied in small aerosol cans or bottles with a built in brush for easy application. It is intended to cover small blemishes or to touch-up exposed cut ends on fabricated parts.

Upon request, and dependent on job size, applicators may supply a limited amount of touch-up paint with completed projects. Touch-up paint is supplied in small aerosol cans or bottles with a built in brush for easy application. It is intended to cover small blemishes or to touch-up exposed cut ends on fabricated parts.

The touch-up paint provided by Linetec is the same fluoropolymer resin-based paint used on your project with a curing additive made available by the paint manufacturers. Each paint type has its own additive that changes the paint from an oven-cured product to a non-oven cured one.

While ADS coatings provide good fade, chalk, UV degradation and chemical resistance characteristic, the touch-up paint does not have the same adhesion or durability as our factory-applied coatings. The touched-up areas are likely to exhibit chalking and fading characteristics at a noticeably faster rate than those with the original factory-applied finish. After only a few years, the contrast will be noticeable. Therefore, it is recommended that touch-up paint be used as sparingly as possible; no more than a few square inches.

What Is Fluoropolymer ADS?

Fluoropolymer resin-based air-dry system coatings, known as ADS coatings, are formulated for repairing, restoring and/or repainting the metal on buildings that have a similarly formulated, factory-applied coating. These ADS coatings also can be used, in the paint facility, for painting materials that will not tolerate the elevated cure temperatures required by typical factory applied fluoropolymer coatings.

Fluoropolymer resin-based air-dry system coatings, known as ADS coatings, are formulated for repairing, restoring and/or repainting the metal on buildings that have a similarly formulated, factory-applied coating. These ADS coatings also can be used, in the paint facility, for painting materials that will not tolerate the elevated cure temperatures required by typical factory applied fluoropolymer coatings.

These ADS coatings only can be applied by a licensed fluoropolymer applicator, such as Linetec and our field service and restoration team. Based on a fluoropolymer-acrylic resin system, these coatings provide good fade, chalk, UV degradation, and chemical resistance characteristics.

What Should I Expect for a Warranty?

When applying touch-up paint to your project, use extreme caution as excessive use will void the original finish warranty. Because of the serious liabilities involved with touch-up paint, Linetec prefers not to manufacture or sell touch-up products. In limited circumstances, Linetec will sell larger quantities (quarts) only under a no liability clause with an authorized signature.

Any job requiring Linetec onsite field repair, using Fluoropolymer ADS because of an unlikely Linetec finish issue, would be warranted in parallel with the original Linetec factory warranty.

Linetec onsite field repair and restoration projects utilizing the Fluoropolymer ADS system are warranted on an individual basis. Warranty options are dependent upon the base metal condition, site location, type of damage, etc. A warranty for field finishing may be up to 5 years from date of completion.

How Is Touch-Up Paint Applied?

For proper adhesion and aesthetics for years to come, it’s important to follow touch-up directions carefully.

Procedure: When applying touch-up paint, remember that less is best. Apply with as small an applicator brush as possible. For small imperfections, such as a surface scratches, a brush similar to a finger nail polish applicator is best. Dip the brush half the length of the bristles into the paint. Tap the brush against the side of the container, but don’t wipe against the lid. Hold at the handle near the base and apply light pressure with the fingertips to make the bristles flex slightly. Feather the touch-up paint into the scratch using as little paint as possible.

Applying touch-up with a wide brush or anything other than a small artist’s brush is not recommended.

Surface Preparation

- Clean the surface of any dirt, oil, grease, etc. The most important step in painting any surface is to be sure the area is ready to be coated.

- Sand rough scratches lightly with #400 grit sandpaper.

- Remove sanding dust with a solvent-dampened, lint-free cloth.

- Pretreatment and priming is unnecessary when using touch-up paint on aluminum. (However, if painting over exposed or bare aluminum, see directions below for pretreatment and priming.)

Application of Touch Up Paint

- Temperature of surface and paint must be at room temperature – between 68 and 92 degrees Fahrenheit is ideal.

- Apply the touch-up paint to minor scratches by spraying paint into the container’s cap then lightly dab the brush into the liquid paint. Apply sparingly on the properly prepared surface. Clean the brush with paint thinner after use.

- Spray touch-up paint on rare occasions when a larger surface area needs to be repaired. Spray directly from the aerosol can, holding the can 8 to 12 inches away from the surface to be painted. Press the spray button all the way down. Use steady, even strokes moving back and forth with can.

- Coating should not be applied as a heavy coat at once. To avoid runs and sags, apply the touch-up paint in many light coats, allowing the paint to dry enough to be tacky between each coat. If the paint is applied in too thick of a layer and spread to areas where it is not needed, long-term differential fading between the two coatings will be much more apparent. The same performance cannot be expected from an air-dry paint applied to a surface that originally was factory applied and thermally cured.

Pretreatment: Any time the affected surface exposes the aluminum substrate, it is safe to assume the pretreatment of that area no longer exists and special pretreatment is necessary. Touch-up paint is not designed to be painted over bare aluminum unless it has been properly pretreated.

Aluminum pretreatment preparations can be purchased from your local automotive paint shop or from a pretreatment supply company. Use products such as Amchem Inc Alumiprep #33, Alodine 1201 or an equivalent. The pretreatment should be applied according to label directions on the container.

Prime: After pretreatment, immediately prime the aluminum, following label directions closely.

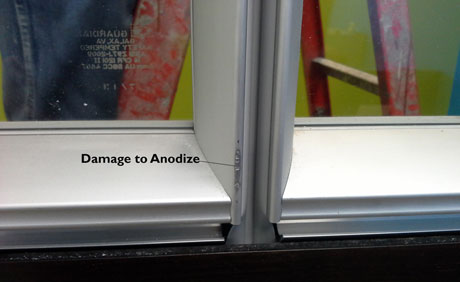

How Can You Touch-Up an Anodize Finish?

Anodize touch-up should not be needed in most cases because anodizing is so hard that it is not easily scratched. Touch-up paint should be used even more sparingly over anodize than over a paint coating. Only touch up the visible raw aluminum in the scratch or gouge using the closest matching paint (Alodine pretreatment should be applied first). In most cases, the match will not be ideal as anodizing is a transparent to translucent coating, while paint typically is opaque and will not blend.

Other fixes include:

Other fixes include:

- Replacing the damaged piece with a new one

- Cladding the damaged piece with a new factory-anodized piece

- Clean, pretreat and paint the entire assembly

None of the above “other fixes” are good ones. The best repair is not to allow the material to get damaged in the first place. The number one cause of damage on the jobsite is failing to protect the anodized material from harsh chemicals, such as concrete, mortar or muriatic acid, brick wash. If reasonable care is taken during handling, and high and low pH chemicals can be avoided, repair and/or touch-up of an anodize finish will not be needed.

Summary

Almost any field situation can be repaired by Linetec’s field-service. Freight damage, graffiti removal, anodize refinishing, ding and dent repair, metallic field finishing, interior or exterior repair, etc. – all qualify as potential field repair projects.

Almost any field situation can be repaired by Linetec’s field-service. Freight damage, graffiti removal, anodize refinishing, ding and dent repair, metallic field finishing, interior or exterior repair, etc. – all qualify as potential field repair projects.

For more than 40 years, fluoropolymer resin-based finishes have held the position as the world’s premiere exterior metal finish. These ADS coatings offer similar, superior weathering properties and can be field-applied on almost any building material, restoring surfaces to last and look like new.

The durable properties of fluoropolymer ADS coatings resist marring and abrasion, withstand airborne pollution without staining or discoloring, and retain their excellent appearance over time. These coatings require little maintenance and can be easily cleaned with mild detergents.

For any repair other than a small scratch or blemish, we strongly suggest that you call on our Linetec Field Repair Department to inspect the situation and determine the best suitable paint or repair procedure for you. Surface preparation, application and finish should all be properly executed for a long lasting finish. A minor mistake in any segment of repair will cause major problems over time.