Whether you’re manufacturing commercial curtainwall or residential sliding doors, today’s owners and occupants expect a fenestration system with high thermal performance to improve interior comfort and energy efficiency.

Aluminum has consistently proven to be the material of choice for fenestration framing because it is strong, corrosion resistant, fabrication friendly, long-lasting, infinitely recyclable and can be finished in an almost unlimited choice of colors. It also is a good conductor of thermal energy, which means the framing members need to be physically separated to avoid unwanted heat transfer.

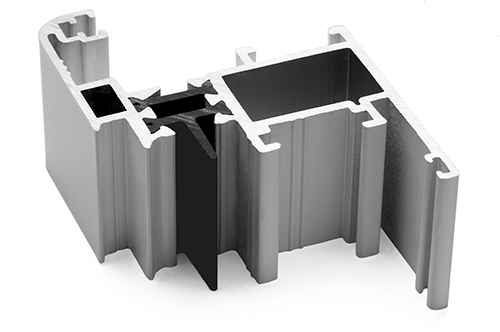

Increasing the separation width of the thermal break cavity and adding an insulating polyamide thermal barrier system between the aluminum framing members, manufacturers can confidently meet their customers’ highest thermal performance needs and energy-saving goals.

Partners in polyamide thermal strut

Helping your products achieve their optimal performance and value, Linetec draws from our long partnership with Technoform to deliver high-quality thermal strut. We begin with two separate extrusions which will become the exterior and interior framing, and join them with the polyamide strut as a thermal barrier. We offer varying sizes, from just 10mm up to 100mm, to match your system’s specified cavity separation width.

“The advantage of a thermal barrier is that it’s customized specifically for each system type,” said Technoform’s Chad Ricker. “Historically, there’s a misconception that thermal barriers are only needed in cold climates. Studies show that there are also opportunities for energy savings and comfort benefits from using high thermal products in warm climates as well as cold.”

“The primary benefit is the reduction of energy transfer through frames, which can lower the heating/cooling loads for building infrastructure. Additional benefits come from providing natural daylighting, which can reduce energy loads and provide many health and productivity benefits,” he continued. “A common theme for all projects is that occupants want more windows. It’s really about having a good performing product, so you can create the interior environment you want, regardless of project type.”

Engineered for exceptional performance

Technoform’s insulating strips are made with multidirectional glass fibers oriented in three dimensions. Beyond disrupting thermal conduction, their engineered composition protects against heat distortion, resists impact and enhances sheer strength. Improving load transfer, they provide exceptional structural performance and mechanical response.

“Thermal barrier products and their installation processes are absolutely critical to the overall structural integrity and air/water performance of the entire fenestration system,” emphasized Ricker. “Polyamide thermal barriers are more than 500 times less conductive than aluminum. The lower conductivity of thermal barriers allow systems to obtain optimal U-Factor and resistance against condensation, while keeping the best qualities of aluminum fenestration products.”

Since 2013, Linetec and Technoform have helped manufacturers like Wausau Window and Wall Systems’ INvent.PLUS™ windows reach NFRC U-Factors as low as 0.16. The aluminum framing with extra-wide 44mm polyamide thermal barriers is combined with triple glazing for energy-efficient results.

Ricker added, “In addition to increasing thermal performance, thermal barriers can house gaskets for sealing against air or water, be utilized to house or mount hardware, create drainage solutions for water mitigation, can have foam applied or legs to break up convection, or create opportunities for lowering sound transmittance.”

Another benefit of polyamide is that “there are no Red List chemicals in our product, and we have achieved a Cradle-to-Cradle Gold material health certificate,” noted Ricker. “There are no harmful chemicals, and the entire process is virtually silent. When designing or specifying a thermal barrier, it’s important to consider the differences in the processes and choose a product that creates a good work environment for whomever is making your materials.”

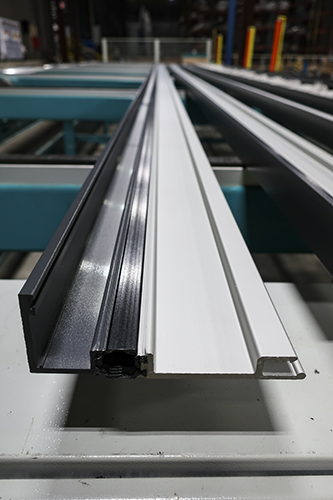

Single-pass solution adds savings

Within the comfort of our quality-controlled facility, Linetec is proud to offer manufacturers a 90-degree thermal strip with a single-pass solution. This allows us to install the thermal strip simultaneously on two planes of material. This industry-leading capability gives you the option of using a single assembly – rather than multiple pieces – without compromising energy efficiency or condensation resistance.

Saving you time, labor and associated costs, our single-pass process minimizes inconsistencies and waste, while holding to your customer-specified performance requirements for a high-quality finished product. As part of our rigorous quality control process, our in-house team tests for angularity and shear strength.

“Shear value is the amount of force it takes to displace, or ‘shear,’ the thermal strut from the aluminum,” explained Ricker. “The fenestration manufacturer’s system engineer calculates this value for their unique system, but 200 pounds per inch is a typical range.”

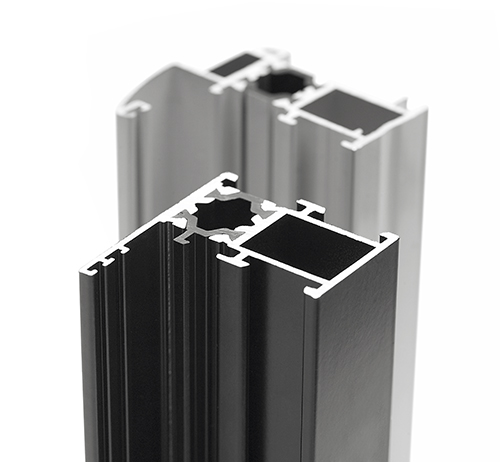

Dual-finish design flexibility

Along with reliable performance, thermal strut also offers design flexibility and aesthetic versatility with “two-tone” dual finishes. Distinct colors and finishes may be used on each extrusion profile. The inside and outside aluminum profiles can be finished in anodize, liquid paint or powder coating depending on its end-use requirements.

Finishes suitable for exterior applications like Class I anodize and 70% PVDF painted coatings are recommended on outside framing members. Different colors, textures or specialty finishes, including coatings with antimicrobial protection, can be applied on the inside framing to complement the interior design or high-touch surface needs.

Proven process, quality results

After the aluminum framing has been finished to your precise instructions, Linetec follows AAMA QAG-2-12, “Voluntary Quality Assurance Processing Guide for Polyamide Thermal Barriers” industry standard, in conjunction with Technoform’s proprietary recommendations.

Our three-step process for thermal strut involves:

- Knurling – To ensure adequate shear strength of the combined profiles, we condition the interior cavity of each extrusion to give the surface its “teeth” that “bite” and hold the strut in place.

- Insertion – As the finished aluminum material runs through the first knurler, the strut slides into the extrusion cavity. With the strut in this extrusion, it then moves to the second knurler where it is properly aligned with the other half of the assembly. Once the strut is in place, the second extrusion slides over the first. The combined assembly is connected by two knurled extrusions held together with thermal strut.

- Crimping – The combined aluminum assembly is sent to the crimping, or rolling machine where three sets of wheels rotate and mechanically lock the strut in place between the aluminum extrusions.

For the best results, Technoform’s Ricker offered a reminder: “The process should begin with a fabricator designing in accordance with the AAMA TIR-A8-16, which addresses the structural performance considerations for manufacturers. We always suggest manufacturers specify polyamide part numbers, as well as the required shear values for composite assemblies, on their assembly drawings. This provides clarity and ensures the assembled composites meet all design criteria.”

Your specifications set the standard

At Linetec, you’re not limited by straight lines. We also offer thermal improvement with stretch forming services for curved creations. When using thermal strut, it’s best to shape the aluminum first, then finish the entire extrusion, and finally to add the thermal barrier that forms the bond between the two extrusions and the strut.

With each new individual assembly, we work with you to determine the proper set-up. When you need a particular assembly reproduced, we reference previous machine settings as the guideline and confirm the performance meets your current requirements.

Ricker concluded, “The choice of thermal barrier is extremely important to the overall performance and quality of a system. It’s critical to give it the attention it deserves. Working with a partner like Linetec as a single source solution, manufacturers not only benefit from higher quality, but also from reduced risk and faster lead times.”