HIGHEST-PERFORMANCE COATINGS.

LINETEC IN-HOUSE BLENDING

The in-house blending lab allows Linetec to match colors and blend paints without having to wait for the paint suppliers to blend and deliver them to Linetec.

Linetec’s blending lab has six individual mix and match color systems, encompassing the three leading high-performance paint manufacturers, giving us the ability to meet or exceed all AAMA paint specifications: 2603, 2604 and 2605. These paint blending systems give us the ability to fully control the color match, ensuring customers receive the best color consistency possible.

linetec's precise color match process

Perfecting technologies to ensure the correct color match with in-house blending.

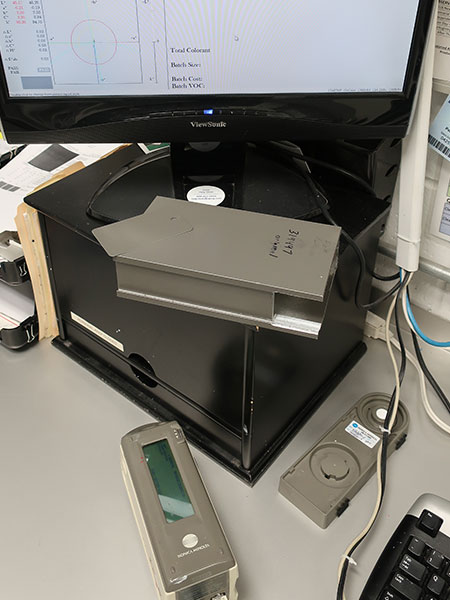

COLOR MATCH COMPUTER SysTEM

The color match computer, called a Spectrophotometer, scan color samples and provide the recipe of tints and bases to precisely match the color sample. Using this equipment, and years of experience, Linetec’s lab technicians can match anything from a piece of metal, to a section of masonry, to a swatch of fabric.

24-48 hour customer samples

Color matches are created on small metal panels and sent to the customer for approval. Having in-house blending capabilities allows us to better meet our customers’ needs in hours not days or weeks. Typically customer sample and color match requests are processed and completed in 24 to 48 hours for most in-house blendable colors. Upon color approval, Linetec will produce the coating in the blending kitchen where anywhere from one to several thousand gallons of the specific color can be produced.

STORAGE VAULT ELIMINATES COLOR VARIATION

In addition to Linetec’s expansive color matching and paint producing capabilities, is our paint storage vault. Within the storage vault, a working inventory of approximately 15,000 gallons of paint is maintained. This stock is based on current and future customer needs, assuring the exact color on final project material. This eliminates any potential color variation when the entire project is not painted at the same time.

SAMPLE COLOR CHIPS

Linetec can supply color sample chips for any order or quote. Requests for samples can be made on-line, with our Quoting Department or Inside Sales Representative. Typical response time is 48 hours on most In-house blendable colors and all anodize colors. Non in-house blendable samples may take up to 2 weeks depending on the paint system, type, color, and vendor.

Each color sample will have key information documented on the back of the chip. Color name, finish type, finish code, number of coats required, and if it is in-house blendable or non in-house blendable. Samples are shipped standard ground delivery.

REQUEST COLOR SAMPLE CHIPSlinetec color intermix system

From Blending Kitchen to the Sample Color Chip Oven and straight to your office.

Blending kitchen

Linetec’s in-house color matching system utilizes multiple interfaced computer and color match systems – including Hunter Lab Spectrophotometers – to match and blend PVDF resin and baked enamel coating systems.

intermix color system

Linetec’s color intermix system holds over 50,000 unique colors in its database, with the ability to match almost any color in-house. You can be assured that Linetec will provide the perfect color for your project.

sample color chip oven

Paint color chip samples are created by Linetec’s in-house lab technician per request and cured in our sample chip oven.

The Linetec associate verifies color after the paint chip has cured, prior to the samples being sent out to the customer.

AAMA Verified Component Licensee

American Architectural Manufacturers Association, a material-neutral organization, is the source of performance standards for the fenestration professionals of window, door, skylight, curtain wall and storefront manufacturing companies.

LEARN MORE

SPECIALTY FINISHES

As your Single Source Solution we offer custom options and specialty finishes such as Wood Grain Finishes, Copper Anodize, Spattercoat and textured Terra Cotta Coatings.

LEARN MORE

ENVIRONMENTAL COMMITMENT

Linetec has earned a long-standing reputation as a leader in environmentally-conscious practices and finishing options. For more than a decade, environmental responsibility has been written into our core values.

LEARN MORE

RESOURCE CENTER

Our technical experts at Linetec provide valuable industry education of high-performance architectural finishes to architects, engineers, specifiers and manufacturers.

LEARN MORE

Photo credits: Linetec

Architectural Paint

Architectural Paint Types

Color Charts

Request Samples

Request for Quote

PAINT SPECS & PROCESS

Linetec Paint Process

In-House Blending

Quality Control

Material Size Guidelines

AAMA Specifications

Warranty Information

Environmental Considerations

PAINT MAINENTANCE

ANODIZE FINISHING

Copper Anodize

Eco-Friendly Anodize

Anodize Color Samples

Request for Quote

Declare | Red List Free

ANODIZE SPECS & PROCESS

Anodize Process

Racking Methods

Quality Control

Material Size Guidelines

AAMA Specifications

Warranty Information

Environmental Considerations

ANODIZE MAINENTANCE

LINETEC SERVICES

Linetec Managed Inventory (LMI)

Stretch Forming

Linetec Trucking

Thermal Pour & Debridge

Thermal Strut

Brake Metal & Fabrication

Stock Flat Sheet & Extrusion

Packaging & Shipping

SPECIALTY FINISHES

Copper Anodize

Bordeaux Anodize

Wood Grain Finishes

Terra Cotta Coatings

Spattercoat

Request A Quote